Influence of humidity on electrophysical properties of protective DLC layers of GEM detectors

News, 12 March 2025

Scientists of the Institute for Nuclear Problems and the Faculty of Physics of the Belarusian State University (INP BSU), together with employees from the Laboratory of High Energy Physics at JINR, studied the influence of humidity on the electrophysical properties and charge transfer mechanism in nanoscale diamond-like carbon (DLC) coatings. The researchers concluded that the influence of humidity is caused not by a change in the structure of the coating itself, but by the formation of an additional layer of water molecules on its surface, which adsorb and dissociate, creating a conductive film. It is this process that leads to a decrease in the total electrical resistance of the system. In addition, the results of the study demonstrated an opportunity of creating a resistive DLC coating-based humidity sensor.

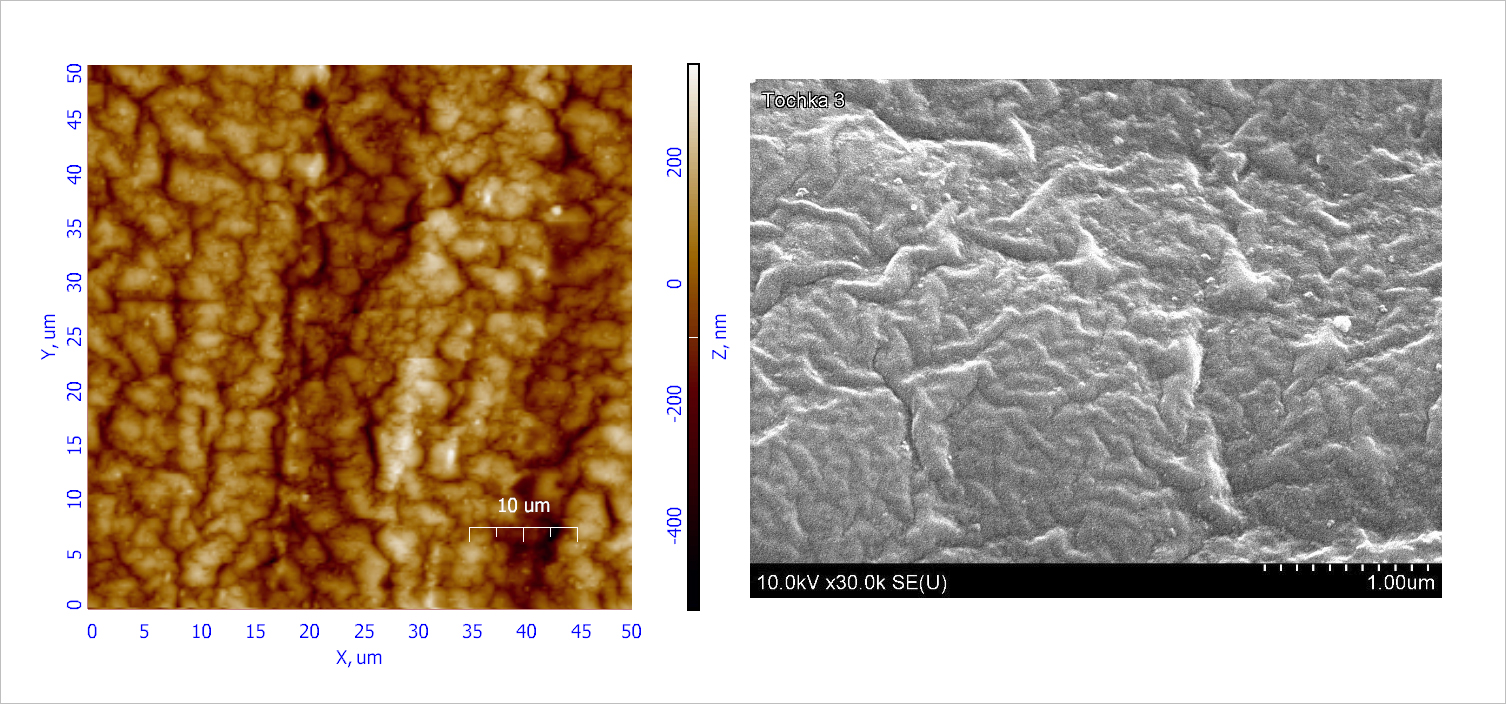

Pic. 1 Image of atomic force (left) and scanning electron (right) microscopy of the DLC coating surface with a thickness of 62 nm

Pic. 1 Image of atomic force (left) and scanning electron (right) microscopy of the DLC coating surface with a thickness of 62 nm

Diamond-like carbon coatings are indispensable protective layers for optical elements and wear-resistant coatings for moving parts. Along with this, research conducted at CERN and JINR opened up the opportunity for another important application of DLC coatings: they are used as resistive coatings for electrodes of gas-discharge detectors of ionising radiation. Such coatings increase the stability of the detectors and their resistance to spark discharges. “One of the key characteristics of DLC coatings in this context is their electrical resistance, which, as we demonstrated in the experiment, is significantly influenced by measurement conditions, particularly ambient humidity,” co-author of the study, an INP BSU employee Ilya Zur noted.

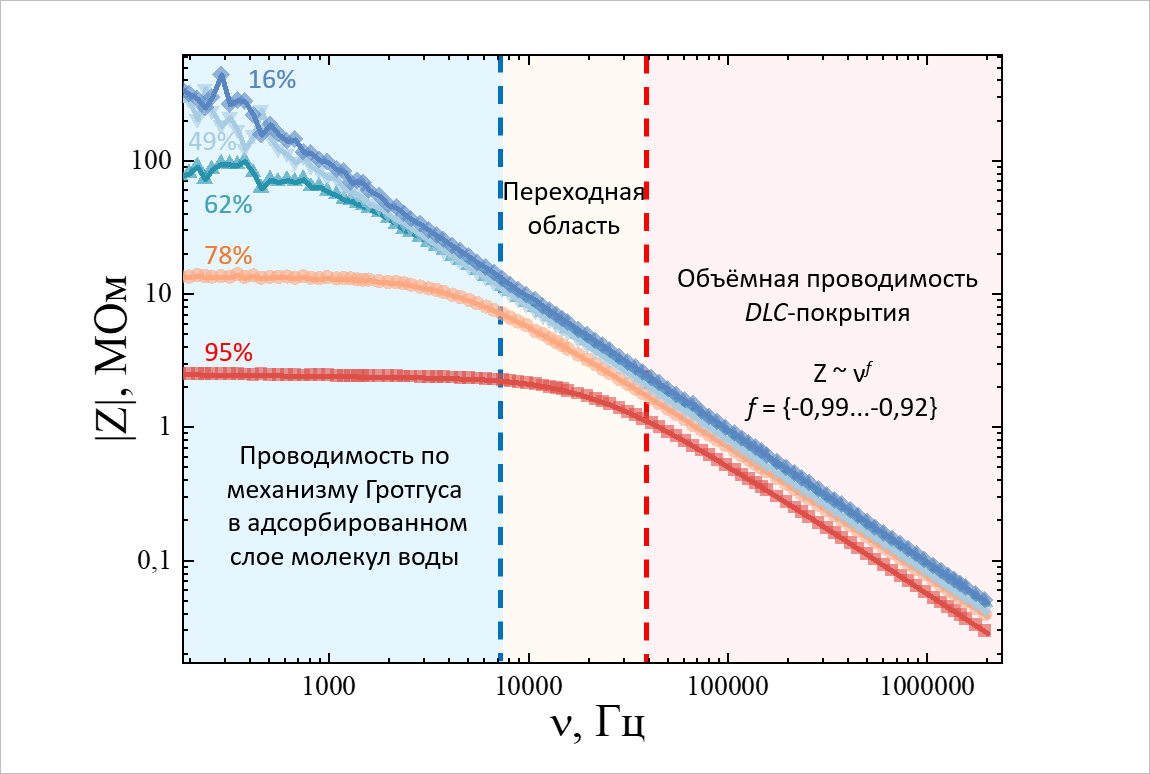

Nanoscale DLC coatings on substrates made of acrylonitrile butadiene styrene (ABS plastic) were studied. They are characterised by a linear current-voltage characteristic, a decrease in electrical resistivity from 12 Ohm⋅m to 3 Ohm⋅m, and a wetting angle from 52° to 38° with an increase in thickness from 54 nm to 71 nm. The relative dielectric permittivity of DLC coatings ranges from 5.6 to 6.5. At the high frequency limit, it is completely determined by the real part. It is proposed to consider the conductivity in the “DLC coating//adsorbed layer of H2O molecules” system as a combination of two mechanisms: the hopping conductivity of electrons in the volume of the DLC coating and the proton conductivity in the adsorption layer of water molecules by the Grotgus mechanism. It was experimentally established that a change in air humidity in the range from 16 % to 95 % leads to a decrease in the electrical resistance of the system up to 103 times, from 1000 to 11 mOhm.

Pic. 2 Frequency dependence of the impedance of DLC coatings with a thickness of 54 nm for 95, 78, 62, 48, and 16 % humidity

Pic. 2 Frequency dependence of the impedance of DLC coatings with a thickness of 54 nm for 95, 78, 62, 48, and 16 % humidity

The obtained results are of great practical importance for the correct measurement of electrical resistance of resistive coatings before their installation in detectors. In addition, the high sensitivity of DLC coatings to humidity and their rapid response to its changes open up prospects for using them as a material for resistive humidity sensors. This can be an alternative to conventional materials used in such devices.

The article entitled “Influence of humidity on the electrophysical properties and charge transfer mechanism in nanoscale diamond-like carbon coatings” was published in Carbon in 2025. The article is written by I. A. Zur, J. A. Fedotova, A. S. Fedotov, Y. Y. Shmanay, A. K. Fedotov, A. A. Kharchanka, N. I. Gorbachuk, E. A. Ermakova, S. A. Movchan.