First Prototype Magnetic Shield for the JUNO Experiment arrived at DLNP

News, 20 August 2020

The first prototype magnetic shield for photomultiplier tubes (PMTs) of the OSIRIS facility in the JUNO experiment has arrived at the Dzhelepov Laboratory of Nuclear Problems.

Even a weak magnetic field impairs characteristics of large PMTs, and that is why their perfect functioning can be ensured only by their shielding from the Earth’s magnetic field. To this end, magnetic shields (MSs) for the above project were designed at DLNP.

State-of-the-art material with ultra-high magnetic permeability, so-called metallic glass, an amorphous iron, can be regarded as a special feature of these MSs. The metallic glass production process involves quick heat removal in order to prevent the formation of crystal structure elements, which ensures magnetic permeability 100 times higher than in “standard” permalloy (permalloy is a nickel-iron alloy with soft magnetic properties). It means that we need 100 times less material to create the shielding equivalent to that from permalloy.

DLNP leading specialists speak about Magnetic shield for PMTs and the the JUNO experiment

The material amount is an important factor since the OSIRIS facility is designed for measuring ultra-low levels of radioactivity in liquid scintillator before its filling into the main JUNO detector. The presence of natural radioactive impurities in structural materials near the OSIRIS active volume impairs the facility’s sensitivity and this is why the strong control of their concentration is required.

All the materials used for magnetic shield manufacturing were thoroughly selected to guarantee the gamma-ray background no higher the one from PMTs themselves. Metallic glass does not lose magnetic properties under mechanical deformations and can be used without annealing, technically complicated for large items. This is a definite advantage when compared to permalloy.

Another difficulty in elaborating MSs was a necessity of metallic glass protection against a corrosive medium because PMTs with MSs will be submerged into ultrapure water. For this reason, the composite coating of metallic glass was preferred. Moreover, 12 MSs for the muon veto will be fabricated from low-cost fiberglass plastic and 64 SMs for the main detector from carbon plastic. The requirements on material radiation purity of the main detector MSs are stricter than those of the muon veto MSs. Therefore, fiberglass plastic with a higher potassium content is not suitable for the production of the main detector MSs.

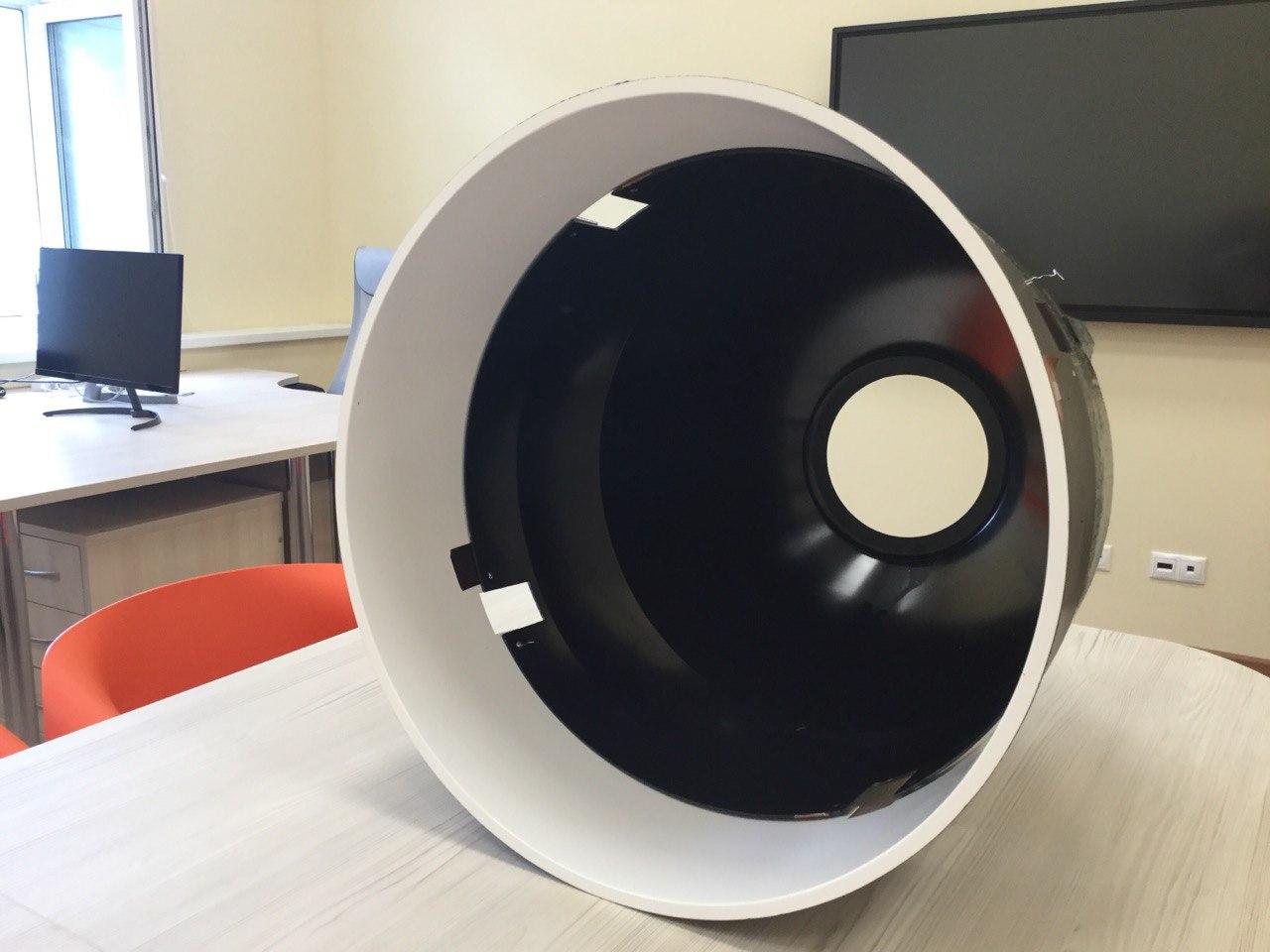

Each MS comprises two modules, the main one designed as a truncated cone and the additional one as a cylinder. The latter will also serve as a light concentrator, and for this reason it is coated from inside with white reflecting material. Other surfaces are coated with black gelcoat and matted to prevent unwanted reflections. Another special design feature is a radio-frequency shield, a foil layer inside of the composite.

By the end of the year, according to the agreement between DLNP and the RWTH Aachen University, all 76 MSs will be manufactured and shipped to China.

Oleg Smirnov, Candidate of Physics and Mathematics

The Joint Institute for Nuclear Research has been participating in the JUNO collaboration for over five years. The Jiangmen Underground Neutrino Observatory, now under construction, will be situated 150 km to the west of Hong Кong. The JUNO experimental hall is located 700 m deep underground. The detector filled with 20000 t of liquid scintillator will use 15000 PMTs for detecting the scintillation light produced in collisions between neutrinos and hydrogen atoms. The principal objective of the experiment is to study neutrino oscillations between three neutrino types, electron, muon, and tau-neutrinos. Relative masses of all three neutrino types are intended to be determined, or in other words, the fermion mass hierarchy problem is to be disentangled.