Current status of work at MPD

News, 27 September 2022

Work continues at the Laboratory of High Energy Physics JINR on assembling the solenoid of the MPD Detector (Multi-Purpose Detector). One of the two main detectors at the NICA Accelerator Complex will be devoted to studying hot and dense baryonic matter in heavy ion collisions at the collider. This year, the MPD solenoid magnet connection to the control Dewar has been upgraded, the magnet correction coils have been assembled, and many other tasks have been completed. By the end of December, a cooling test is planned to be carried out at MPD.

It should be reminded that that the key element of the MPD Detector, a superconducting solenoid 4.6 m in diameter and 7.5 m long, was delivered to JINR in November 2020. In 2021, it was installed in the partially assembled magnet yoke. Partial assembly of the solenoid and phased tests continue in 2022.

In December 2021, density and tightness tests of the solenoid began: the integrity of the nitrogen shield circuit, the volume of the solenoid, and the helium circuit of the superconducting cable cooling cavity were checked. As a result, a leak in the shield circuit was detected, which was localised and repaired by VBLHEP specialists in cooperation with representatives of the solenoid manufacturer ASG Superconductors (Genoa, Italy).

Sophisticated solutions

The installation of the unit connecting the solenoid to the control Dewar, part of the solenoid’s cryogenic system that operates according to the thermos principle, was to begin after those tests. A refrigerant must be supplied through it to cool the solenoid’s nitrogen shield, which is necessary to prevent the more expensive and colder helium from evaporating, and the superconducting cable to ultra-low temperatures close to absolute zero. The operating temperature of the solenoid will be 4.5 K., as the solenoid cable acquires superconducting properties at this condition.

Control Dewar mounted on a platform

Control Dewar mounted on a platform

Modernising the coupling unit

The manufacturer, when delivering the solenoid to Dubna, did not supply some elements of the unit that connect the solenoid to the control Dewar: expansion bellows, adapters, and bimetallic adapters. The unit itself was not designed to allow access to this area without disassembling the entire system, including the removal of the control Dewar, which meant that MPD staff members would not have had access for repairs if necessary. Therefore, the engineers at the VBLHEP Design Bureau made a tough choice and completely redesigned the assembly, including redesigning the pipelines themselves and cutting the top plate. After cutting the plate, the MPD team ran a computer modelling of the magnetic fields and verified that the final homogeneity of the magnetic field would not be affected by this modification. Regardless, the cut part will be replaced by a segmented one. This will fill the empty area even more densely than previously intended, replicating the shape of the slab at the back end.

The components for the upgraded unit design have been ordered and manufactured. “The unit now has a collapsible vacuum cover and the pipeline components are detachable connections. This design allows you to get to any part of the pipeline without removing the cryogenic equipment on the platform,” Konstantin Mukhin, Deputy Chief Engineer at VBLHEP, MPD’s operations head, explained.

Konstantin Mukhin in the photo

Konstantin Mukhin in the photo

The unit has now been partially assembled and locally tested for tightness. The magnetic circuit will be fully assembled then, the support rings will be installed on it, and part of the MPD top platform will be placed on. The control Dewar is now in its working position on the platform. The Laboratory programmers are writing the software required for its operation. The Dewar connection to the solenoid was completely redesigned in September, and it is scheduled to be completed by the end of October and tested with connection to the magnet monitoring and control system.

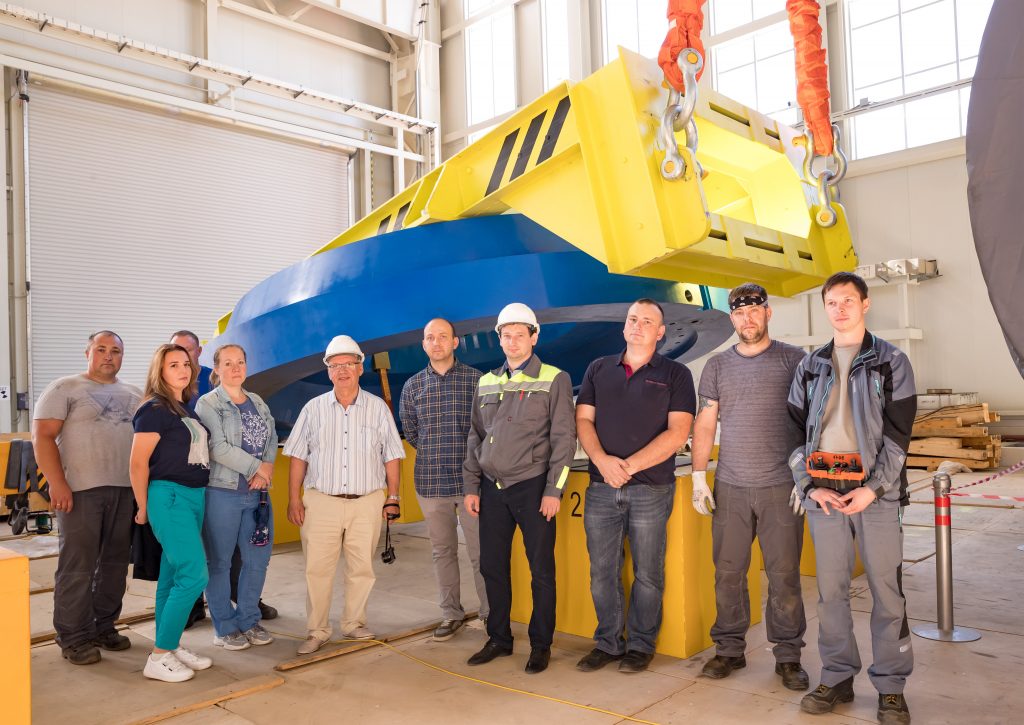

Correction coil assembly

In addition to the superconducting solenoid itself and the steel cover (magnetic circuit), the MPD solenoid magnet also includes two correction coils which round out the magnetic field at the ends. Another major piece of work was dedicated to their installation in June and July 2022.

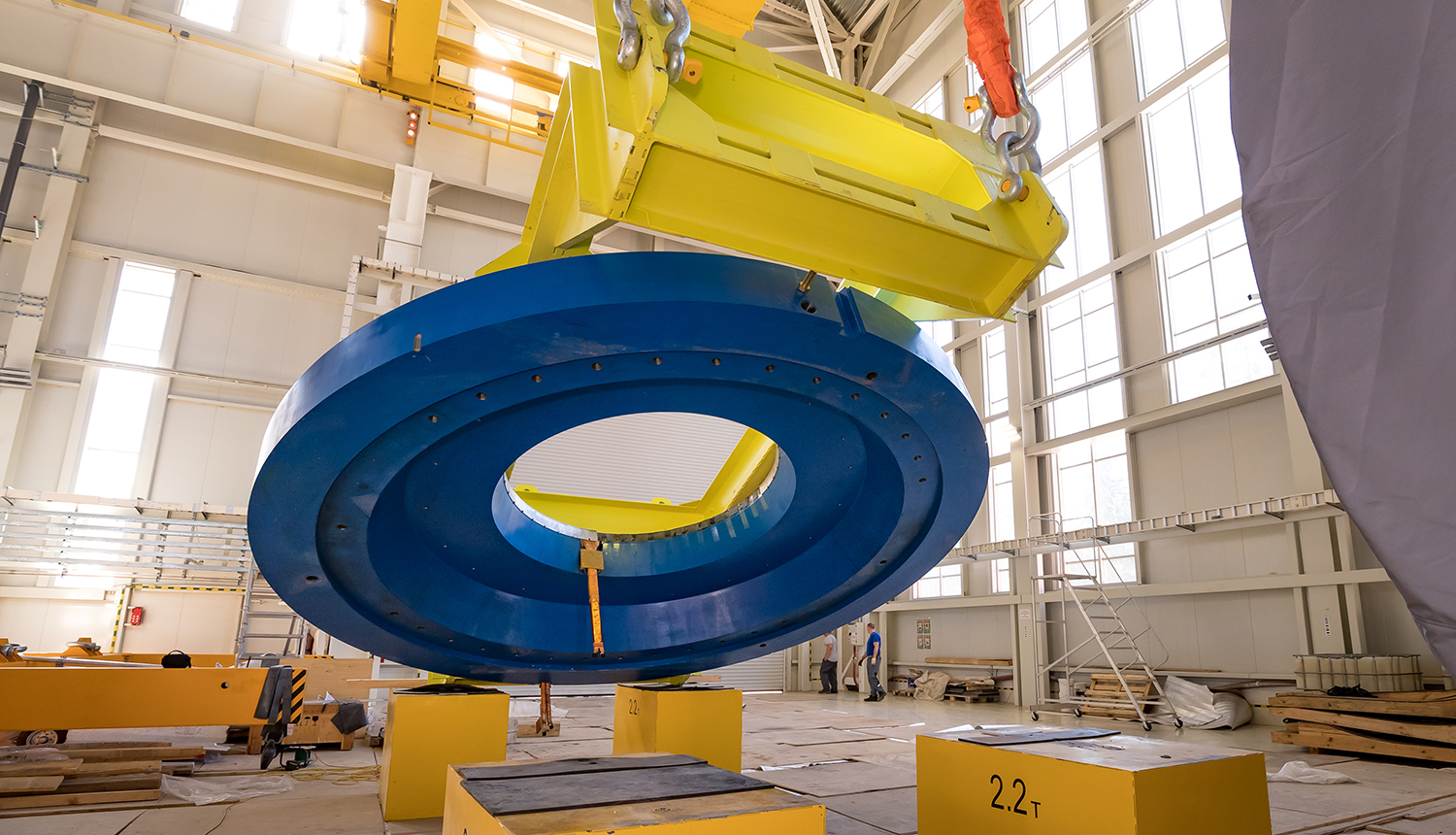

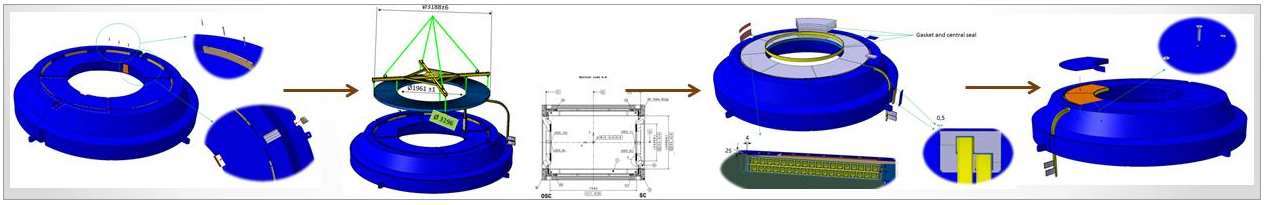

Stages of installing the coil in the pole

Stages of installing the coil in the pole

Correction coils are needed to correct the magnetic field in case of inhomogeneity. They are warm, which means that they are cooled with distilled water.

The coils, each weighing 2 tonnes, were placed in 40 tonne steel poles according to the ASG manufacturer’s plan and the technology developed at VBLHEP and then rolled onto moving jigs. This will ensure that the coils will be placed in the solenoid’s support rings later.

At the end of these operations, VBLHEP specialists measured the coordinates of the coil and pole axis with a laser tracker. Measurements showed that the W coil (West) was only 0.7 mm out of coil-pole alignment and the E coil (East) was 1.2 mm, which fitted into a tolerance of 2 mm. “The position of these coils was checked both horizontally and vertically. Theoretically, the coil could have collapsed under such a heavy weight when it was placed in a vertical position, but it did not. The shift was a fraction of a millimetre,” Konstantin Mukhin commented.

Other achievements

Another challenge the team was able to solve over the summer was to refine the MFS system, a heater that maintained the temperature when the solenoid’s nitrogen shield cooled down. “There was a number of problems there: the level sensor did not work, and the power dependence of the heating elements (3 of them) on the output temperature was not clarified. However, it must be very accurate: the solenoid should cool down at a rate of 1 K per hour, with the variation at input and output of the solenoid itself not exceeding 20 K. These are very tough conditions, and the MPD team has worked hard to test this device and find the optimum operating regimes for it. It is now ready for manual operation as part of the cryogenic system. But we plan to continue working in this direction and, after a number of experiments, develop a cooling algorithm with correction factors, switching the MFS to automatic operation,” he said.

On 20 September, another significant part of the cryogenic system, the satellite refrigerator, was transported from the JINR warehouse to the MPD experimental building. The refrigeration is being assembled, as well as the solenoid power and control electronics cabinets, after which local tests are planned.

The external power supply system is modified to meet the requirements of the solenoid. Strabag, the general contractor for the construction of the NICA complex, installed the external water cooling system components and brought them into the collider building, and installed the pipelines and units in the MPD pavilion. The distilled water tanks in the collider building are being installed.

Aims for the stars

There are some difficulties in carrying out works due to the suspension of the solenoid manufacturer ASG Superconductors as part of the solenoid supervision project. The company refers to the sanctions imposed on Russia. Despite JINR’s international status, it is not possible to agree on a continuation of their involvement now. Cooperation with other equipment suppliers from EU countries such as Germany, Poland, and the Czech Republic has been suspended indefinitely. Most of the cryogenic equipment (pipelines, heater shells, nitrogen tanks, etc.) was ordered from the EU, where its production is currently frozen and the finished equipment cannot be shipped.

Under the circumstances, part of the MPD project team focused on analysing the documentation of the various solenoid systems that had already been delivered. Some of the issues that arise can be resolved internally. Some equipment can be reordered in Russia or from other countries.

General view of the main elements of the magnet assembly

General view of the main elements of the magnet assembly

Taking into account the delay that will occur when reordering some of the equipment in the RF, a temporary solenoid cooling scheme has been developed: according to it, mobile nitrogen and helium tanks will be used to replace stationary ones.

Western partners not only supplied all the cryogenic equipment, they were also responsible for the magnet power supply, monitoring, and control system. In the absence of a connection to ASG, and the difficulties in using the original system (access denied), as an alternative, the team is considering the possibility of building this system themselves.

“We will have documentation for every step that we do everything according to the technology and that we don’t go beyond the allowable parameters of deviations. Should the situation improve and ASG, as the manufacturer and responsible for receiving the field, return, these documents will allow us to confirm that work has been carried out without disturbing the assembly process, especially for hidden works,” Konstantin Mukhin said.

The MPD team is planning an initial cooling of the solenoid under a temporary scheme starting in December. Under favourable conditions, a test run of the power system using the existing original software will also take place between December 2022 and January 2023.

- to install the 3 remaining plates of the magnet core, measuring the position of all the magnet elements together;

- to place the upper platform with the cryogenic and vacuum equipment in the working position;

- to assemble the cryogenic system on a platform with tightness tests;

- to install pipelines from the MPD building to the new cryogenic section;

- to develop temporary software to monitor and regulate the operation of a cryogenic system that is not part of the MPD control system.

Before the end of 2022, the MPD team expects:

Nevertheless, VBLHEP specialists have to take into account possible deadline shifts. The reasons for this are numerous: changes to the supply pattern, lack of documentation of critical schemes and algorithms, lack of access to the magnet control system software, and other circumstances.